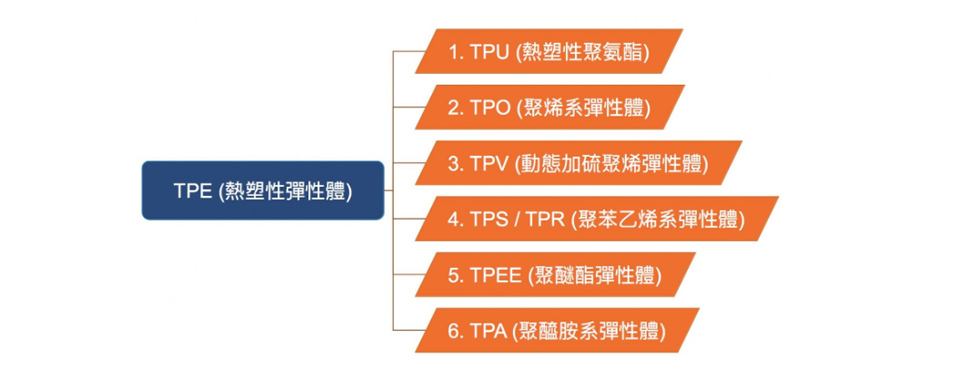

Q5: What are the characteristics of the six major categories of thermoplastic elastomers (TPE)?

1. TPU

Thermopolyurethane (TPU) is abbreviated as TPU. Mainly based on its soft segment divided into two series of polyether and polyester, TPU has the following main features in performance and processing:

- With strongest wear resistance among all types of TPE

- High strength, high toughness & high transparency.

- Good fatigue resistance, cold temperature resistance and oil resistance

- Having hydrolysis problems

- Insufficient weathering (UV) resistance

- Large residual stress of the finished product and easy to stick

2. TPO

The hard segment of TPO is a polyolefin such as PP or PE, and the soft one is rubber such as EPDM (EPDM), TPO is obtained from well blended of the two.

TPO has the following main features in terms of performance and processing:

- With smallest specific gravity and low price.

- Cold and heat resistant, good acid and alkali resistant

- Weather & ozone resistance, and good electrical insulation.

- Easy for processing and forming specifically for large products

- Vulnerable to non-polar solvents such as gasoline and aromatic solvents

- Low tensile strength (filling reinforcement)

- Large degree of permanent compressed deformation

- Inferior wear resistance & tensile resilience

3. TPV

The dynamic vulcanizate (Thermoplastic Vulcanizate) is abbreviated as TPV. TPV can be many different kinds of specifications depends on the type and combination of hard and soft segments, the most typical one is PP-EPDM. TPV has the following main features in performance and processing :

- Good oil, weather and heat resistance

- Better mechanical properties than TPO, with lower hardness than TPO

- The lowest permanent compressed deformation among TPE.

- Environmental friendly, non-toxic, recyclable, and can be used for medical equipment.

- No transparency

- Inferior wear resistance than rubber and TPU

- The price is much higher than TPO

- Low flow coefficient and surface is sometimes prone to flow marks.

4. TPS / TPR

Polystyrene elastomer (Thermoplastic Styrene) is abbreviated as TPS or TPR. Polystyrene elastomers can be divided into two categories: hydrogenated SBS and hydrogenated SEBS. SBS is susceptible to oxygen, ozone and ultraviolet light due to its double bond in the molecule. On the contrary, Due to the influence of ultraviolet rays, SEBS and SEPS have no such concerns because their molecules are saturated bonds.

TPS has the following main features in performance and processing :

- The finished product has a wide range of physical properties which is easy to process.

- With highest elongation and the best resilience

- Can act as a compatibilizer and modifier for many different engineering plastics

- Sense of touch is closed to the rubber and silicone, with lowest hardness among TPE

- The finished product has poor stain, wear and oil resistance.

- Low-hardness finished products are sometimes easy to produce oil

- SBS series, poor heat and weather resistance

5. TPEE

Thermoplastic Polyester Elastomer (TPME) is abbreviated as TPEE. TPEE can be divided into: polyester-polyether type; polyester-polyester type & liquid crystal type TPEE-polyester type. The most commonly used and most demanded is polyester-polyether TPEE. The hard segment is represented by PBT. TPEE has the following main features in performance and processing:

- It has the highest heat and high load resistance and also high resilience.

- The repeated fatigue characteristics are excellent and the properties are strong.

- Better low temperature flexibility than TPU

- It is resistant to oil, chemicals and chemical solvents.

- It is not easy to obtain low hardness product.

- Limited processing conditions and require more precision processing machines

- Expensive

- Harder than normal rubber

6. TPA

Thermoplastic Polyamide Elastomer (TPA) is with polyamine as a hard segment. Polyether or polyester with a low Tg value is a soft segment. TPA has the following main features in performance and processing:

- Good processing formability (good dimensional stability)

- Nylon-like toughness and wear resistance.

- Good heat and oil resistance.

- Good low temperature impact resistance.

- Expensive

- Insufficient rubber elasticity

- Recycled material is easy to change color

- Easy to hydrolysis in boiling water